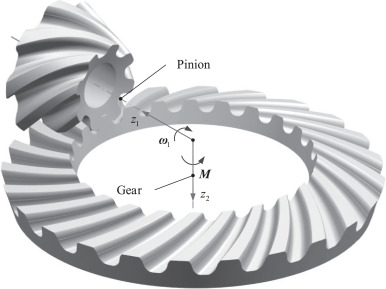

Spiral bevel gears

Spiral bevel gear, or bevel gear in general, is a gear in which the teeth are skewed, and not all teeth engage together, to allow the wheel to turn freely. It is a set of gears which are offset from each other, so as to form a ‘deformed’ shape, and is sometimes used to form the teeth of another gear, as when a spur gear is used to form the teeth of a helical gear.

This type of gear is used primarily in the mechanical arts, to form universal joints, transmissions, or differentials. Spiral bevel gears are gears with teeth that have a spiral or helical shape. They are also called worm gears, screw gears, helical gears, or screw-like gears. A bevel gear is a toothed wheel that is used to transmit power. It is also called a bevel-cut gear (a cutter gear) which is produced by cutting a bevel into the teeth of a circular shaped box, then cutting along the bevel to form the teeth into a curve.

A gear is a device with teeth or toothed wheels that meshes with another to transfer torque from a driving mass to a driven mass. In the case of a bevel gear, the driving mass rotates and the driven mass turns in the opposite direction to the driving mass. Whereas other gear types transfer torque indirectly, bevel gears transfer torque very directly. Bevel gears are classified by the shape of the teeth, which can be circular, rectangular, or spiral.

The most common type of bevel gear is the spiral bevel gears, which has helical teeth. Other common types of bevel gears include the square bevel gear, the rectangular bevel gear, and the worm gear. One of the most common uses of bevel gears is in the form of universal joints, where a shaft rotates in one direction and a ball joint rotates in the opposite direction. Bevel gear types: There are a variety of bevel gear types, including straight cut gear, spiral cut gear, and helical cut gear.

Each of these is produced by cutting a bevel into the teeth of a circular shaped box, then cutting along the bevel to form the teeth into a curve. Some bevel gear types, such as spiral cut gear, are designed to align the gear teeth in a spiral shape to improve gear performance. Other gear types, such as helical cut gear, are designed to form the teeth into a curved shape to improve gear performance. Bevel gears are used in many different applications, such as in transmissions, differentials, and universal joints. They are also used to form the teeth of other types of gears, such as spur gears, which are used to form linear motion devices such as pinions or helical gears, which are used to form rotary motion devices such as worm gears. Some examples of applications that use spiral bevel gears are automobiles, bicycles, and machinery such as drills or saws.

Some common types of bevel gears are spiral bevel gears, straight bevel gears, worm gears, and helical gears. Bevel gears are available in a variety of types and designs, each of which has its own unique properties and uses. The most common bevel gears are the spiral bevel gears, the spur gear, and the helical gear. Other common types of bevel gears include the worm gear, the universal joint gear, and the differentials. Some bevel gears, such as worm gears, are also used in other applications. Bevel gears are classified into two main types: spur and spiral bevel gears. The first type, a spur gear, is a toothed wheel that is used to transmit power. It is also called a bevel-cut gear (a cutter gear) which is produced by cutting a bevel into the teeth of a circular shaped box, then cutting along the bevel to form the teeth into a curve. The second type, a spiral bevel gears, are a toothed wheel that is used to transmit power.