Hammer forgings

Hammer forgings is one of the most common machines used for forging. The most critical issues that arise during development of hammer forging technology are:

- Development of defect free forgings (ie: The absence of underfilling and defects of continuity in the die cavity as well as favorable microstructure)

- Achieving good die life

- Selecting the correct equipment and calculation of required number of blows

The primary benefit of hammer forgings is their strength and durability. They are stronger than steel forgings and can be used to make products such as crown wheel, wheelchairs, office chairs, fences, and more.

This makes them an excellent choice for products that will be used and exposed to the elements, such as wheelchairs.

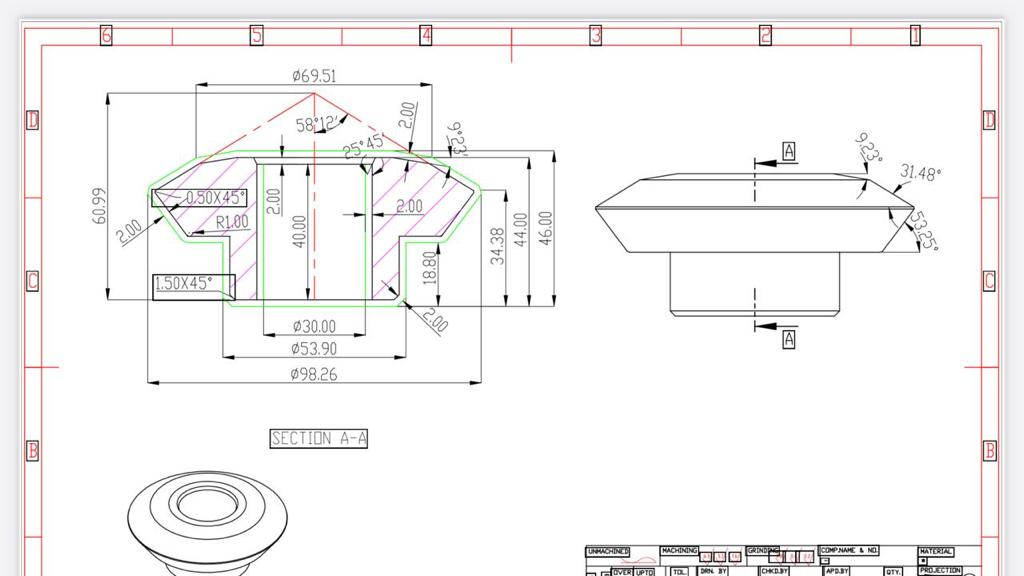

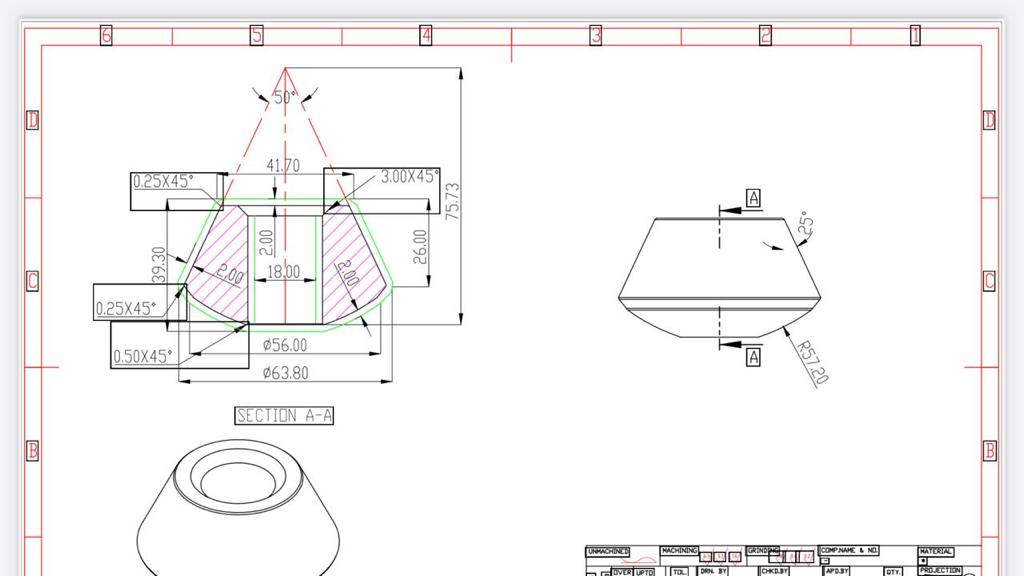

Product Pictures

Hammer Forging is the best way to machine parts with your 3D printer. It gives you the strength, stiffness, and toughness of steel, with the durability of plastic. It’s the perfect material for making parts that will last a lifetime. It’s so strong that it will never warp or collapse without support.

watch hammer forgings

We’ve built a strong reputation for our products and our people, and now we want to use that to build a stronger future.